- Fibre Plug / OFP® Solder Barrier

An organic paper plug used to create a solder barrier in open bottom receptacles. Designed to help prevent solder from wicking up the barrel of the receptacle during a reflow soldering operation. Once soldering is complete, the mating lead knocks the plug out of the receptacle upon insertion and the plug can be discarded. Learn More.

- Electro-Vibratory Plating

- An electroplating system where the parts are processed in a vibrating basket which ensures uniform plating thickness and avoids damage to delicate parts.

- Electroless Plating

A plating method where material is applied to a part using acid or solutions. This method primarily differs from an electroplating operation in that an electric current is not used to induce the plating deposit generation.

- Early Engagement

A contact clip designed to form a strong connection with a mating lead/pin without needing to pass the full length of the contact clip. Useful in applications where the mating lead is short in length. View Examples

- Dual Entry Receptacle

A receptacle containing contact clips at both openings or containing an individual contact clip that is suitable for either top or bottom entry. Allows for more versatile use when compared to single entry female receptacle products. View Examples

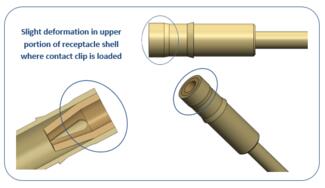

- Bulging

A slight and uncontrolled deformation of the receptacle shell that might occur after a contact clip is inserted during the receptacle assembly process. Most commonly a result of the receptacle shell having a thin wall, which is due to the coaxial hole diameter and the outer diameter being comparable in value. Typically results in a .001”-.003” increase in the outer diameter of the receptacle shell located near the contact entrance. Can typically be averted by adding a shoulder to the receptacle shell or increasing the thickness of its walls.

- Gold Plating

Gold is commonly used as the top plate for many different interconnect components and electronic devices. Mill-Max offers standard gold plating options ranging from a flash plating to 50 µin minimum, with options for both nickel and copper underplates; customer-specific plating finishes are also available upon request. Benefits of a gold-based finish include low and stable contact resistance along with superior protection against corrosion. Application-dependent factors such as environment, cycle life, concerns of gold embrittlement and cost can help decide which thickness option to use for the gold layer.

- Extraction Force

Sometimes known as the withdrawal force, this is the force required to remove a mating lead or pin from a contact clip. The value of this force is primarily driven by factors such as the specific contact clip selected, the base material of the contact clip, and the shape and diameter of the mating lead. The extraction force is also typically lesser in magnitude when compared to the same contact clip’s insertion force. Graphs illustrating the extraction forces for each contact clip can be found online or on the Receptacle Contact Data catalog pages.

- Spring Force Constant

(Conducted on a MM # 0900-X Spring Pin Connector)

k = Force (60) - Preload (25)/Travel (.0275) = 1272.73 g/in.

Preload = 25 g

Force = 60 g

Travel = .0275"

- Shoulder (Flange)

An external rib or lip machined on most pin, receptacle, and spring pin components that is typically the largest external diameter. Most often located on one end of the part but can also be found near the center in certain designs. Its primary function is to assist in board assembly by orienting the product in the mounting hole and providing added support during solder or press-fit mounting. In spring pin and receptacle products, this feature also plays a pivotal role in the assembly of the component.