- Pick & Place

An assembly process by which automated equipment is used to place a broad range of electronic components onto a printed circuit board quickly and precisely. A pick & place machine accepts tape & reel packaged parts, which are extracted individually from their tape pocket by a robotic arm fitted with a nozzle, and mounted in the desired location on the PCB. Parts may be assembled with a pick & place clip, typically removable, which provides a flat top surface for improved handling. Learn More

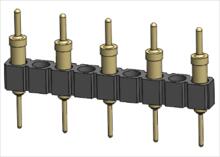

- Double Tail (Header) Pin

A male pin that has been machined with tails on both ends. The most common usage for this style product is for one tail to be solder mounted into a through hole on a PCB, while the other is used as a lead for mating into a female interconnect component such as a receptacle or socket. However, the product can also be utilized to generate an electrical connection by solder mounting it into through holes on two separate PCBs or by mating it between two female receptacles or socket components. This style product is often designed with a press-fit retention feature, allowing for assembly into an insulated housing to form a male header. The tails can either be identical on both ends or have differences in their diameters and lengths, allowing for further versatility. View Examples

- Discrete

- Referring to an individual pin, receptacle, or spring pin component rather than an assembled connector. A connector assembly is created by loading one or more discrete components into an insulated housing. Discrete components can be better suited for inconsistent and non-standard footprints, or applications where a housing would interfere with the neighboring or mating components.

- Contact Sizing

- A value-added process that can be provided to discrete receptacles or socket connectors, typically to yield lower insertion/extraction forces. Prior to the parts being received by the customer, a pin lead with a diameter on the higher end of the contact clip’s acceptance range will undergo one mating cycle with the product. This process slightly pushes open the fingers of the clip, resulting in a looser fit-up with the mating lead upon subsequent cycles.

- Uniform Orientation/Alignment

In a connector featuring multiple positions of a solder cup pin, receptacle, or spring pin, uniform orientation specifies that each individual cup in a row is aligned toward the same direction. This allows for a simpler, neater soldering process since each row of wires can be assembled from the same side of the connector in an orderly manner.

- Universal Series Bus (USB) Connector

A common type of interface or connector that allows devices to communicate with a host controller such as a personal computer, for data, signal exchange or charging. Examples of peripheral devices typically connected by USB include external hard drives, mice, keyboards, printers, scanners, cameras and other media devices. Mill-Max offers a wide array of USB sockets designed for both SMT and hybrid style mounting. View Examples

- Soldercup

A type of wire termination feature that consists of a drilled hole at the end of a pin, receptacle, or spring pin with a radius cutout. This cup feature eases the insertion of the wire and provides better visibility while soldering. Wires as large as 14AWG to as small as 26AWG, and potentially smaller, can be assembled quickly and efficiently. View Examples

- Selectively Loaded/Populated

A connector design where the insulated housing isn’t uniformly populated with the same exact pin, receptacle, or spring pin in all available mounting hole positions. Rather, the arrangement may include empty, unpopulated positions or switch between using different components in the same assembly. One example of a selectively loaded connector could be a nine-position strip header loaded in only five positions. This assembly would be considered selectively loaded as it alternates between a pin position and an empty unloaded position. Another example could be a four-position strip socket which uses one type of receptacle for the first two positions, and a different receptacle for the last two positions.

While selectively loaded connectors are often provided as custom oriented solutions, Mill-Max does offer a few standard series in this particular style. View Examples

- Open Frame

A type of DIP insulated housing where there are one or more open/hollow sections in the center of the component, similar to that of a cut-out window. These features help minimize the amount of board space the connector takes up by allowing for additional components to be mounted to the board within these open sections. They can also aid in the inspection of the solder joints by providing further visibility when compared to a closed frame product. View Examples

- Gull Wing

A SMT termination style that is commonly utilized in Mill-Max connectors. A gull wing termination is characterized by the solder tails of the populated pins or receptacles being bent outward, resembling a gull. These bent tails are surface mounted to the board via rectangular solder pads specified prior to soldering. This termination style results in increased solder joint strength and permits easy visual inspection of said joints. Mill-Max offers gull wing SMT termination options in both male and female interconnect packages, including DIPs and single & double row SIPs. Learn More.