Frequently Asked Questions at Mill-Max

Sales Customer Service FAQ's

- Can we make custom pin receptacles or connector assemblies?

- What are Mill-Max's purchasing terms and conditions?

- What is the lead-time on custom products?

- Can we pay a premium to get parts faster?

- Are your parts available in surface mount?

- Why are your part numbers so long?

- What is the International Harmonization Code for your products?

- What is the ECCN Number for your products?

- Does Mill-Max offer RoHS products?

- Do you offer Lead-Free Connectors and Contacts?

Applications and Design FAQ's

- What is the current rating for Mill-Max male printed circuit pins?

- What is the largest acceptance range for the Mill-Max female receptacles?

- Can discrete pins or receptacles be supplied on Tape & Reel?

- Does Mill-Max cross to stamped and formed parts?

- Does Mill-Max provide any suggestions for press-fitting, footprints, etc.?

- Which press-fit feature is best suited for my application?

- Does Mill-Max offer non-magnetic parts?

- Can Mill-Max provide tighter tolerances than what is listed in the catalog?

- What is the minimum quantity for custom solutions?

- Is bulging in the clip assembly area always expected?

- What is the minimum distance the mating pin should protrude beyond the contact/clip?

- What is the suggested mating pin diameter for a Mill-Max Receptacle?

- What options are available for applications higher than 150℃?

- Does Mill-Max machine materials such as stainless steel or beryllium copper?

- Does Mill-Max manufacture Pogo Pins?

- What is the easiest way to way to search for products on the Mill-Max website?

- Why can’t Mill-Max part number 0291-0-15-15-16-14-10-0 be located online?

- What are the root, main causes for premature failures for the Spring Loaded Connectors?

- Where can swage and crimp tooling be purchased?

- Do you have a competitor cross reference?

- Where can operating temperatures and material properties be found?

- Does Mill-Max offer any parts on Kapton Tape or can they be provided?

- What is the deepest end hole (coaxial hole) Mill-Max can provide?

- Does Mill-Max offer over-molding capabilities?

- Are Mill-Max Spring-Loaded Connectors sealed and/or waterproof?

- Are Mill-Max Spring-Loaded Connectors lubricated, and if not, is there a lubrication recommended?

Sales Customer Service FAQ's

-

Can we make custom pin receptacles or connector assemblies? Yes! As a matter of fact, application specific interconnects are what we do best. Whether it's changing a diameter, a length, or a hole size, we can produce exactly what is needed for your application. We are able to turn around custom products quickly, at a reasonable price and in many cases a low minimum. Start designing by reviewing our standard offerings on our website or contacting an applications engineer today.

-

What are Mill-Max's purchasing terms and conditions? All orders placed directly with Mill-Max are subject to our terms and conditions. To view them click here.

-

What is the lead-time on custom products? Custom products can have varying lead times depending on the application. We have been known to turn around prototypes in as little as 2 weeks, where more specialized designs can take up to 12 weeks. The quickest way to get your design started is to select a standard using our product finder, then click on the ”Customize this Part“ button found on the product details page.

-

Can we pay a premium to get parts faster? Every order is important to us and we have some of the best lead times in the industry. Typical lead times range from 3-12 weeks depending on the complexity of your part. We assure you, we will do whatever is possible to meet your delivery needs.

We have over 200 machines running 3 shifts 5 days a week with a set production schedule. We are able to produce over 100 million pins per week and are very often ahead of schedule, many times resulting in deliveries earlier than expected. If you would like us to try to improve our delivery please feel free to contact us. We will do our best!

-

Are your parts available in surface mount? Yes, we do offer surface mount products. We offer surface mount connectors, sockets, and pins. To see our many SMT offerings begin your search by using our product finder.

-

Why are your part numbers so long? Believe it or not, every digit of our part number has a meaning. Our numbers are constructed so we can get most of the information about the part from the number itself. From the part number we can determine type of part - socket, pin, or receptacle, and what plating is on the shell and contact.

We have tens of thousands of part numbers and have never had to make a change in the format of our number system since we instituted it over 45 years ago.

-

What is the Harmonized Schedule (HS) Tariff Classification Number for your products? The Harmonized Schedule (HS) Tariff Classification Number for MILL-MAX products is 8536.90.4000, terminals, electrical splices and electrical couplings.

-

What is the ECCN Number for your products? In accordance with the U.S. Department of Commerce, Bureau of Industry and Security (15 CFR parts 730-774), items listed on the Commerce Control List (CCL) require an ECCN and are subject to Export Administration Regulations (EAR.) Mill-Max is a manufacturer of electronic components used for a wide array of applications. Your anticipated use and country of destination may categorize the product as a controlled material. Please refer to the EAR website for your specific application as required.

-

Does Mill-Max offer RoHS products? Yes. Most Mill-Max products are available in both RoHS compliant and non-compliant versions. The status of each individual part number on our website on the product details page or datasheet of each part. Typically, if a product is not RoHs compliant, the plating choice will be the reason. All of our products have distinct part numbers that describe the content and construction. Identification of RoHS compliant products is provided in our product advertisement, on our website and on product labeling wherever applicable. We strongly recommend customers re-qualify new lead-free RoHS compliant product before implementation into existing designs. For more information visit the ROHS information page.

-

Do you offer Lead-Free Connectors and Contacts? In most cases our high-reliability electrical connectors can be manufactured from lead-free alloys to meet your application needs while meeting Mill-Max’s stringent standards and industry-leading build quality. We are committed to environmental compliance globally, manufacturing connectors that align with multiple international regulations for sustainability. For more information, please contact an applications engineer.

Applications and Design FAQ's

-

What is the current rating for Mill-Max male printed circuit pins? The current rating is typically a measured function of the female socket/connector. The amount of current a solid, male, brass pin can tolerate is a direct relation of the heat displaced based on current and the ability of neighboring components to handle displaced heat. Maximum Current and Maximum De-Rated Current can be found on individual Product Detail pages and datasheets.

-

What is the largest acceptance range for the Mill-Max female receptacles? .084”-.102” (2,13 – 2,59 mm). For more information on acceptance range, compliancy, and current rating, check out our Engineering Notes on The Contact Clip, the Heart of the Mill-Max Receptacle or search online using our product finder.

-

Can discrete pins or receptacles be supplied on Tape & Reel? Yes. Customers should ensure their Pick & Place Machine has the proper nozzle or they have means to obtain the proper nozzle before pursuing this option. Typically, press-fit parts are not good candidates for Tape & Reel due to the press-fitting requirement. However, the new high end Pick & Place machines do have the option of installing press-fit nozzles. A minimum quantity of 1 reel will be required for Tape & Reel parts. The amount of parts per reel can range from 200 parts up. You may review our complete list of parts available on tape and reel or use our product finder to further narrow your search.

-

Does Mill-Max cross to stamped and formed parts? Mill-Max uses high speed, precision screw machines to manufacture pins, receptacles, and Spring-Loaded Connectors. If you are in need of a low cost alternative to a stamped product, a precision-machined product would not be the best suggestion. If you are in need of a solution to solve inadequate electrical or mechanical performance of the stamped product, a precision-machined part would be an excellent solution. Typically, a custom solution can be created or developed to emulate many stamped products.

-

Does Mill-Max provide any suggestions for press-fitting, footprints, etc.? For learning best practices when designing and using Mill-Max products try reviewing our “Engineering Notebooks”. Information focusing on internal contacts/clips, hole-sizes for press-fit requirements, swage & crimp tooling and more can all be found here.

-

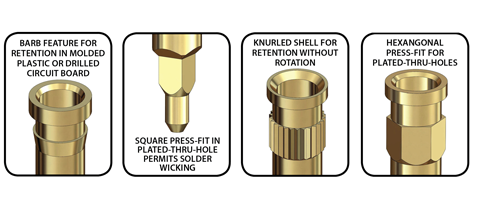

Which press-fit feature is best suited for my application? Below is a general guideline which displays press-fit features and when they should be (properly) used. Additional information focusing on press-fitting and parts can be found in our engineering notebook, Introduction to Mill-Max Press-Fit Technology.

- Barb feature for retention in molded plastic or drilled circuit board.

- Square press-fit in plated-through-hole permits solder wicking

- Knurled shell for retention without rotation

- Hexangonal press-fit for plated-thru-holes

-

Does Mill-Max offer non-magnetic parts? For non-magnetic applications, Mill-Max stocks a .093” diameter specialty brass which contains less than .05% of ferromagnetic materials. It is suitable for most non-magnetic applications. The typical brass alloy materials Mill-Max machines, across all stock sizes, contain iron up to .35% maximum, meaning it has some very low magnetic properties. Depending on the application and the requirements, brass with this amount of magnetic material may or may not be acceptable. Regardless of the brass chosen, the larger concern is the nickel plating used as a barrier plate on brass parts to prevent zinc migration. For non-magnetic applications, the nickel is replaced by thicker copper under plating. Gold is then typically plated over the copper for the finished plating; check out our complete list of plating options for more information.

-

Can Mill-Max provide tighter tolerances than what is listed in the catalog? For some features, Mill-Max can hold machined tolerances to +/- .0005" (.0127 mm) before plating. Typical manufactured tolerances can be found here.

-

What is the minimum quantity for custom solutions? Discrete pins, receptacles, and spring-loaded have a minimum order quantity of 1,000 pcs. For custom connector assemblies the minimum order quantity should equal at least 1,000 individual contacts in the assembly. For instance an assembly with 10 pins/contacts would have a minimum quantity of 100 pcs.

-

Is bulging in the clip assembly area always expected? For end holes where wall material is lacking or thin, insertion of an internal contact/clip will typically create bulging of .001-.003" (.0254 - .0762 mm), which is expected. For more details on design considerations, check out our engineering notebook.

-

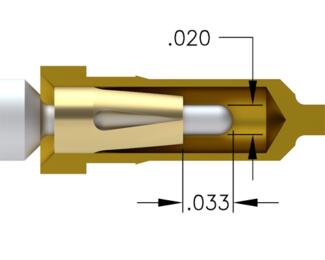

What is the minimum distance the mating pin should protrude beyond the contact/clip? To ensure a good solid electrical and physical connection between the mating pin and receptacle, Mill-Max suggests having the mating lead exceed the tines of the contact/clip by approximately .020-.025”+ (.508-.635 mm) Scoring, marking, or grooving on the male mating pins are all positive signs of a good physical and electrical connection between the female receptacle and the male mating pin.

When designing an interconnect always try to select a Mill-Max contact with a mid-range near your pin diameter. -

What is the suggested mating pin diameter for a Mill-Max Receptacle? Ideally, the Mill-Max contact clip selection should have a pin acceptance mid-range, near the diameter of the mated pin.

-

What options are available for applications higher than 150℃? Mill-Max offers high temperature equivalents to the standard beryllium copper contact/clips. These contact/clips are typically used in applications such as down-hole, burn-in, or where temperatures will exceed 150° Celsius. The available substitutions can be seen in our engineering notebook on High Temperature Beryllium Nickel Contacts or you can view a partial list of available hi-temp receptacles.

-

Does Mill-Max machine materials such as stainless steel or beryllium copper? Mill-Max machines Brass Alloy 360, phosphor bronze, or tellurium copper. See our General Technical Specifications for more information.

-

Does Mill-Max manufacture Pogo Pins? Mill-Max manufactures Spring-Loaded Connectors. Spring-Loaded Connectors are commonly used in charging or docking applications, whereas Pogo Pins are typically used in testing applications, such as a bed of nails type application. A Pogo Pin can commonly be manufactured from beryllium copper, which will be harder than the copper alloy used in Mill-Max’s Spring Pin Connectors. For more information view our engineering notebook, Understanding Spring Pin Connector Design.

-

What is the easiest way to way to search for products on the Mill-Max website? The Mill-Max website offers five separate ways to conduct a search for products. Depending on the individual’s knowledge of the product line, some customers may find it easier to search by a picture while others may prefer conducting a search based on text.

The five search options are:

-

Why can't Mill-Max part number 0291-0-15-15-16-14-10-0 be located online? The 0291 base receptacle will be a standard, off the shelf item. Due to the non-standard contact/clip plating choice, this part will not be considered a standard item. The below part number breakdown will help identify and define the digits used in a Mill-Max part. The breakdown of the part number will also apply to situations where customers require a non-standard or high temperature beryllium nickel internal contact/clip.

Mill-Max part number defined:

- 0291-0-15-15-16-14-10-0

- 0291 = Receptacle/Shell Part Number

- -0 = In-House Code

- -15 = In-House Code

- -15 = Body/Shell Plating

- -16 = Contact/Clip Number

- -14 = Contact/Clip Plating Choice

- -10 = In-House Code

- -0 = In-House Code

The Plating Options Pins PDF File will display the plating differences which are available in the center of many product specification pages.

-

What are the root, main causes for premature failures for the Spring Loaded Connectors? Typically, if a customer experiences premature failures, most likely over-compression or side loads has played a part. Most customers, intrigued by the products, will begin compressing them in their hands, putting extreme forces on the plunger and creating a set spring. Once the spring has taken a set, the plunger no longer will return to the original position. Side loads or axial loads will also contribute to binding or sticking, creating stuck plungers. Our recommendation is to protect the plunger from any side loads if possible, along with over-compression. Customers can easily solve this problems by creating a mechanical stop or limit on the application’s compression ability.

-

Where can swage and crimp tooling be purchased? Mill-Max does not manufacture tooling. Daniel‘s Manufacturing Corp. does offer several Positioners designed for specific Pins and Receptacles For additional help designing Swage tooling, contact us to discuss your specific tooling requirement.

-

Do you have a competitor cross reference? The Mill-Max Cross-Reference Search is expanded and updated frequently. When conducting a search using the cross-reference, the less digits entered commonly brings back the most results. For example, if a customer has a FCI part number such as: SIP1X12-011BLF, entering SIP1 would be suggested for the initial search.

-

Where can operating temperatures and material properties be found? Material and plating specifications, documented ratings and ranges can be found her in our General Technical Specifications or on the product details page of any product found on our website.

-

Does Mill-Max offer any parts on Kapton Tape or can they be provided? Currently Mill-Max does offer our 3169 Double Tail Pin loaded on Kapton Tape. Mill-Max has the ability to provide many parts on Kapton Tape however, this may require modification of the pin/receptacle. We also offer many other standard pins, receptacles, and connector assemblies on Tape and Reel for automatic placement.

-

What is the deepest end hole (coaxial hole) Mill-Max can provide? For high speed turning, a hole depth of 5 times the diameter is the preferred maximum depth. If the hole depth exceeds the above factor, the part will be forced to run on a slower machine, raising the cost.

-

Does Mill-Max offer over-molding capabilities? Press-fit or interference-fit is the provided mounting of Mill-Max parts in injection molded insulators/housings. Mill-Max offers several pins and receptacles which have been successfully used by customers in applications requiring over-molding. Mill-Max has the ability to provide custom pins and receptacles with features designed for over-molding, and in some cases may be able to provide a complete over-molded solution for the customer.

-

Are Mill-Max Spring-Loaded Connectors sealed and/or waterproof? A typical Mill-Max Spring Pin Connector is made up of four precision-machined components. The spring pin plunger or tip, when compressed will move inwards in the linear direction, residing inside the pin connector's body, creating an entry point for liquids or contaminants. However a Mill-Max Spring Pin can be installed in its own sealed housing to create a sealed chamber where environments are not friendly. For more details on waterproofing your spring-pin application contact an applications engineer.

-

Are Mill-Max Spring Loaded Connectors lubricated, and if not, is there a lubrication recommended? Mill-Max Spring Loaded Connectors are not lubricated. Customers have used light viscosity, thin metal oils in the past and have had success. Typical applications do not require lubrication.