- Non-Plated Through Hole (NPTH)

- A mounting hole that has not been given a layer of plating on a PCB or housing, such as a molded or machined plastic insulator. When press-fitting, non-plated through holes are suggested for parts that have a barb or a knurl feature.

- Vacuum Pad

A plastic protrusion featured on select DIP sockets that facilitate pick and place handling. On the larger size sockets, there's also a pad beneath for horizontal transfer. View Examples

- Electrical Discontinuity

- A break or interruption in the flow of current in an electrical connection or circuit. Can be indicative of failure or damage to a component within the application, or from excessive shock and vibration.

- Horizontal Mount

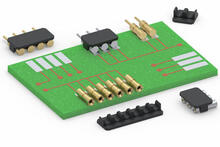

Components which are intended to be mounted horizontally or parallel to the board surface. Often provided in different styles, including surface mount (HSMT), Z-bend, and right angle through-hole.

- Vibration

- A mechanical phenomenon of oscillations usually observed as a shaking or rattling movement. Minimizing vibration in a system and protecting the system from unwanted vibration are common goals in a mechanical design. Excessive vibration onto a component can cause damage such as wear, signal loss and connector separation.

- Vertical Mount

- Components which are intended to be mounted vertically or perpendicular to the board surface. Often provided in different styles, including surface mount, press-fit, and through hole.

- Vent/Vented

A feature on a PCB pin which consists of chamfered cut(s), typically for solder flow and/or to allow gases to escape in a PCB assembly. View Examples

- Positions

- Refers to the total number of populated pins, receptacles, or spring pins present in a connector product. This is dictated by the insulated housing, namely its length, pitch, and number of rows. The total number of positions in a connector can be determined by reviewing the 6th-8th digit in the Mill-Max part number.

- Pitch/Grid/Spacing

- A pre-defined array or pattern of holes in an insulator or housing. The arrangement is commonly defined by pin to pin (pitch) and/or row to row spacing. Common Mill-Max pitch offerings include: 1mm, .050”, .070”, 2mm, .100”, 4mm & .200”. More unique pitch options can be reviewed as custom solutions.

- Cut-out Window

- The removal of material (typically in the center of an insulator or housing) which allows for improved visibility and the ability to place components in the open section. Most commonly provided on BGA and PGA style connectors.