- ZIF

- Zero Insertion Force

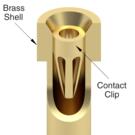

- Shell

A precision screw machined component, typically cylindrical and manufactured out of a brass alloy. Its primary function is to serve as a housing for the contact clip in female interconnect assemblies such as receptacles or sockets. A prevalent feature in receptacle shells is a drilled hole that is machined through the center; the majority are also designed with a flange used to aid in both receptacle and board assembly. In addition, some shells are designed with unique features for press-fitting, solder tails for through-hole mounting, and various types of wire termination features to allow for use in a wide range of applications.

- Pick & Place Cap/Clip

A removable molded plastic cap or clip component provided on certain products packaged on tape and reel. The primary function of this component is to aid in the removal of the part from the carrier tape. It provides a larger surface area for handling and keeps the part centered in the pocket. This component is typically left on the product during the soldering portion of the board assembly procedure, but it is removed shortly after the installation is completed. View Examples

- Open Bottom

A receptacle shell which has a full length internal coaxial hole, making the component hollow or straw-like. This design allows the mating lead or pin to protrude through the receptacle upon insertion. This is especially appealing for pins or leads that are quite lengthy or those who need to be trimmed as a post insertion procedure. View Examples.

- Nail Head Pins

A versatile male pin machined in the shape of a nail. Can be used for a multitude of purposes including board stacking, board to component connections, mating surfaces for spring loaded products, and many more. The main draw of this style of pin is its ability to provide a thru connection while having a low-profile head/largest diameter. View Examples

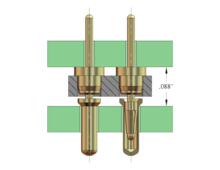

- Mated Height

The assembled height of a pair of male and female interconnect components once engaged. Commonly considered a design constraint when developing PCB assemblies, careful selection of a suitable male + female combination is required to achieve proper stack up (or above-board distance). Mated sets of discrete components or connectors can be considered zero, low, mid, or high profile based on this amount of stack height.

- Light Insertion Force (LIF)

Socket connector products where minimal force is required to mate and de-mate the mating component or device. Primarily used for high position count applications due to the cumulative nature of the insertion force, as well as applications with delicate or fragile mating pins or leads.

- Target

The mating face for a spring-loaded pin or connector which creates an electrical connection when the plunger is compressed up against it. A target may refer to a land/pad on the PCB, or an additional pin/disc component mounted onto the board or housing. Mill-Max target pins are typically round and gold plated, with either a flat or concave mating surface. Offered in both discrete and connector strip options. View Examples

- IP Rating

Measurement of how well a piece of equipment or device can resist penetration of water, chemicals, dust and other fluids or debris. Sometimes known as the water resilience or level of ingress protection a product has.

- OFP® Solder Barrier/Fibre Plug

An organic paper plug used to create a solder barrier in Open Bottom receptacles. Once soldering is complete, the mating lead knocks the plug out.