- Blind Mate

Mating of one or more components where visibility is obstructed or limited.

Typical Blind Mating Connection This process can lead to damage or breakage due to misalignment during mating. To mitigate this risk with pin + receptacle connections, receptacles with generous countersinks/lead-ins are used along with alignment pegs and/or shrouded housings to further guide the mating pin to the center of the receptacle. Spring loaded connections are better suited for blind mates due to the lack of insertion required. Furthermore, customers have used target pins with a concave face to help guide the plunger component of the spring pin towards the center of the target.

- Wrapost (Terminal or Receptacle)

The length of square cross section of certain pins and receptacles which is used for making electrical connections via wire wrapping. Wire wrapping is a process in which wire is wrapped around the post to form a gas-tight connection without soldering.

- Underplate

The plating layer applied to a part before the top plate or surface coating. This layer is typically composed of either nickel or copper, but other materials can be used as well. The underplate contributes to the performance of the total coating by improving corrosion resistance, wear resistance, and solderability, and by also limiting the potential diffusion of base metal elements into the top plate such as .

- Top Plate

- The final or topmost plating layer applied to a part which dictates color appearance; Commonly composed of gold, tin/lead or tin. The top plate contributes to performance of the total coating by improving electrical performance, corrosion and wear resistance, and solderability.

- Thermoset

- Plastic polymers that can only be heated and molded once. This makes them ideal for high temperature applications, as excessive and/or prolonged heat will not change or deform the material. Mill-Max utilizes thermoset materials such as FR-4 (G10) in custom machined plastic housings.

- Thermoplastics

- Plastic polymers that soften when they are heated and solidify again as they are cooled, allowing for molding/shaping operations such as injection molding. Due to their unique chemical properties, thermoplastic materials can be remolded and recycled without negatively affecting the material’s physical properties. All of Mill-Max’s standard connectors that are assembled with molded plastic insulators/housings would be considered thermoplastics.

- Thermal Coefficient of Expansion (TCE)

Expansion of material caused by an increase in temperature.

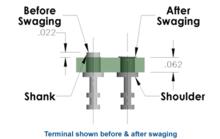

- Swage Mount

A method of mechanically fastening pin terminals to a circuit board, similar in style to riveting. It is commonly used with solder terminals and printed circuit board pins for low to medium volume applications. The swaging technique captures the board between the flared or swaged material and the shoulder of the pin, fastening the pin to the board.

While not formally required, a soldering procedure can be conducted after the swaging process to improve the mechanical and electrical reliability of the connection. Learn More

- Standoff / Mounting (Alignment) Peg

A plastic protrusion at the bottom of certain connectors used to raise the product off the PC board to aid in solder fillet formation, board inspection, flux removal, alignment and cleaning. View Example

- Skiving

The displacement of a thin amount of plating material when interconnect components are press-fitted into a mounting hole. While this is a natural byproduct of the assembly operation, soft plating finishes (such as tin) may yield more noticeable amounts. Skiving may also appear when a contact clip is pressed into a receptacle shell; most often with a tin-plated shell and a gold-plated contact combination.