- Durability

- A product’s anticipated mechanical life expectancy. Typically refers to the insertion/extraction cycles of a receptacle or the compression cycles of a spring pin. The actual mechanical life is a factor of several application-specific variables, such as the environmental conditions and/or mating pin specifications.

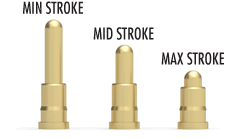

- Max. Stroke

The maximum possible distance the plunger of a spring pin can be compressed or actuated. It is primarily dependent on the characteristics of the internal spring and the construction of the specific spring pin. While it is possible to compress a spring pin to this particular distance, it is not recommended in applications that are looking to maximize both mechanical and electrical performance. However, applications that require minimal cycling may see electrical benefits when compressing the spring pin to its maximum stroke or close to it.

- Mid Stroke/Rated Travel

Fifty percent (50%) of a spring-loaded pin’s maximum stroke capability. This is the minimum travel required to ensure the spring-loaded product meets all stated electrical and mechanical ratings and specifications. All ratings are generated from testing which is performed at mid stroke compression.

- Crimp Termination

A feature provided on certain pins, receptacles, and spring pins that allows for solderless wire termination by deforming the outer diameter of the product. The crimp parts will have a barrel on one end with a blind coaxial hole drilled into it, creating a thin wall which allows the material to be pinched or deformed. These features can accept a range of wire gauges while ensuring proper fit up for greater versatility. After a properly sized wire is inserted into the feature, the retention deformation is generated by use of a crimp tool and positioner. Validation of the retention force between the wire and the product can be evaluated by methods such as a pull test. Learn More

For more information view the following video, .

- Wire Crimp/Termination

An assembly method by which a wire is electrically and mechanically fastened to an interconnect component. This may refer to a soldercup style part, which provides a cut-out for easy access when soldering, or a crimp style part, permitting solder-free crimping into a properly sized barrel. View Examples

- Over Compression

The condition by which a spring pin or spring-loaded connector is actuated past its specified maximum stroke distance. Spring deformation can occur, causing it to bind and remain set/stuck in the same position without returning to its original uncompressed state. A compression of 50% of maximum stroke (rated travel) will ensure the spring-loaded pin meets the stated electrical and mechanical ratings and specifications. As plunger travel is reduced below 50% the electrical performance may degrade while mechanical life may be extended. The opposite is true for compression above 50% of maximum stroke.

- Body

Refers to the central section of a pin, receptacle, or spring pin. Typically machined out of a brass alloy material.

- Plunger

An active driving component, typically driven by a spring.

- Solder Tail

- A machined post or lead which protrudes from the bottom of pin, receptacle or spring pin. For through-hole requirements, the tail feature serves as a stable anchor for soldering and mounting purposes.

- Land/Pad

A typically round, flat, gold-plated conductive surface used as a mating interface for spring-loaded products. These pads are incorporated onto PCBs or electronic devices and allow for electrical connection as the plunger of a spring pin is compressed up against it. While thin pads can be generated during the board fabrication process, they may not provide the durability or adaptability required. In these instances, Mill-Max offers discrete target discs to provide a conductive surface equivalent to that of a pad, but in a more robust machined design. View Examples