- Heat Treating

- The process of using specific heating and cooling cycles to alter the mechanical properties of an alloy. Heat treating can harden or soften a metal depending on the parameters used and the desired physical property of the material within its application.

- Heat Deflection Temperature (HDT)

An industry recognized test for comparing the short term effects of high temperature on plastics.

- Gas Tight Connection

An electromechanical connection of sufficient pressure that prevents the intrusion of a corrosive atmosphere into the contact area.

- Fretting

A form of wear that often leads to or increases the likelihood of corrosion. This wear is often caused by the repeated cyclical rubbing between two surfaces in which one is under a load. In pin & receptacle connections, this wear is often generated between the internal contact clip and the surface of the mating pin. In spring loaded connections, this wear is generated between the plunger of the spring pin and the mating surface or target. Over time, this wear results in the removal of material from one or both mating surfaces, resulting in the appearance of black spots, marks, lines or patches depending on the specific mode of fretting wear. As more debris is accumulated, the wear process by abrasion is accelerated which can then accelerate oxidation as more of the protective layer is removed.

- Free Machining Alloy

An alloy which incorporates additives to make the material easier to machine, providing better surface finishes and increasing tool life. Mill-Max uses free machining Brass alloys with lead as the additive. Learn More

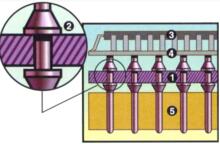

- Floating Contact

Refers to connectors that contain pins or receptacles designed to move up and down freely in an insulator, rather than being retained in place by a press-fit feature. This additional “play” allows the connector to compensate for unevenly dispensed solder paste, mating misalignment and other errors known to increase the amount of stress applied to the connector, PCB and/or solder joints. View Examples.

- Flatness

Sometimes used in place of coplanarity, flatness refers to the amount of variation of a plane or surface.

- Flash (Plating)

- A very thin layer of plating, usually less than 10 micro inches in thickness. Switching to flash plating from a thicker plating option is a common way to drive down the cost of a component, possibly at the expense of durability. This makes flash plating better suited for applications with benign environments that will not see aggressive handling or in ones where gold embrittlement is of concern.

- Machined Plastic Insulator

An insulator fabricated out of large rectangular sheets of plastic being machined with a high-speed drill/router. As there is typically no tooling or fixturing required for production, this type of insulator presents an appealing solution for lower volume production runs and/or rapid prototyping. FR-4 epoxy is the primary material used, with G-30 polyimide offering an alternative for higher temperature applications. Learn More.

- End Stackable

A connector where the dimensions and tolerances of the insulator are precise enough to stack multiple connectors from end-to-end while maintaining the same pin-to-pin spacing throughout adjacent connectors.