- Electroplating

A plating method where material is applied to a part by means of electrodeposition. This commonly involves loading parts into a vibrating basket that is immersed in a plating solution and then applying an electrical current to induce adhesion. Benefits of electroplating include uniform plating thickness, improved plating coverage in small coaxial holes, and preventing damage to delicate parts.

- Electrostatic Discharge (ESD)

The momentary electric current that flows between two objects that may cause damage to electronic equipment.

- Coplanarity

The measurement of multiple points and their distance from a single common plane. Used for surface mount connectors to ensure that all individual pins, receptacles, or spring pins in the array make uniform contact to the board within a certain tolerance. Poor coplanarity may lead to uneven or detached solder joints once the part is assembled onto SMT pads.

- Contact Resistance

- A measure of how difficult it is for current to travel/pass through an electrical interface (may consist of components such as pin + receptacle and/or spring pin + target connector). A higher contact resistance is undesirable because the connection would be more inclined to resist electrical flow. Measured in ohms, this characteristic is impacted by both mating component’s geometry, plating, contact area and normal force. The actual interface typically consists of a contact area much smaller than what is seen by the naked eye, and results in a resistance value that is independent of the standalone resistance for each material in the mated set. An observable voltage drop across the connection occurs due to this resistance.

- Contact Rating

Current carrying capability of a contact measured in amperes with respect to temperature rise above ambient.

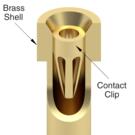

- Contact (and Contact Clip)

The multi-finger spring insert component of a receptacle assembly. Its primary function is to generate the electrical and mechanical connection between a female receptacle and its mating male pin or lead. This is achieved by means of the fingers or tines of the component, which grip the pin/lead upon proper insertion and allow for multiple insertions.

Contact Clips are stamped and formed from Beryllium Copper or Beryllium Nickel for high temp applications. Learn More.

- Constant Usage Temperature (CUT)

Constant Usage Temperature is a measure of the maximum temperature that a material may be exposed to for long periods of time, 1000-1500 hrs., before degradation of its electrical and mechanical properties occurs.

- Compliant Press Fit

A method of mounting an interconnect component into a plated through hole on a PCB using a feature that consists of multiple barbs that are machined on a hollow slotted tail. This termination feature is designed to collapse and conform to the parameters of the plated hole, preventing damage while ensuring a reliable solderless gas-tight connection. Common customer applications include multi-layer board stacks and mating card-edge to card-edge connections. Learn More

- Compliancy

A contact clip's ability to accept multiple insertions and extractions of a wide range of pin shapes and sizes while retaining its original configuration. The acceptance range of the contact will typically be altered after inserting the maximum permissible pin. For example: the #34 contact has an initial operating range from .032" to .046" diameter pins and a compliancy of .010”. After insertion of a .046" pin, the contact is sized, and the minimum pin acceptance becomes .046" - .010" = .036". Thus, the new operating range becomes .036" to .046". The compliancy rating advertised for each of our contacts can be found on the General Contact Information page of our Catalog.

- Clip (Contact)

The multi-finger spring insert component of a receptacle assembly. Its primary function is to generate the electrical and mechanical connection between a female receptacle and its mating male pin or lead. This is achieved by means of the fingers or tines of the component, which grip the pin/lead upon proper insertion and allow for multiple insertions.

Contact Clips are stamped and formed from Beryllium Copper or Beryllium Nickel for high temp applications. Learn More.