Carrier Tape Options for Mill-Max Discrete Pins & Receptacles

For the better part of 20 years Mill-Max has offered its precision turned pins and receptacles packaged on tape and reel for automated pick and place assembly. Many of our customers expect components, regardless of shape and size, to be packaged for automated assembly. At Mill-Max we understand this need in order to maintain the production levels required for efficient and economic production, and have continued to upgrade our in-house capabilities to address these requirements for both through hole and SMT discrete pins and receptacles. Our goal is to offer tape and reel packaging whenever feasible and with our ever-growing advanced tooling and design capabilities we are able to deliver a greater variety of parts on tape and reel than ever before.

All Mill-Max, tape and reel packaging is designed to meet the guidelines of the EIA-481-D standard and we are fully integrated from tape pocket design and manufacturing to packaging the parts on tape and reel. These advantage of keeping all processes in-house, allows us to reduce tooling costs and lead times while meeting the packaging needs of our customers.

The following are some examples of the many styles of pins and receptacles we are able to package on tape and reel.

Traditional Style Receptacles (Typical Orientation):Sometimes referred to as PCB sockets, micro-plugs or connector jacks the traditional Mill-Max receptacles are the most amenable to tape and reel packaging. These parts are typically larger at the top and smaller at the bottom, allowing the part to sit snugly in the pocket with minimal lateral movement. Mill-Max receptacles with no tail and a closed bottom, or open bottom fibre plug type, fit into this category.

|

| ||

SMT Receptacles for Bottom Entry (Inverse Orientation):As design engineers are challenged to reduce product size they often come up with creative ideas to make connections board to board or component to board. One example is to use a reversed receptacle designed for through hole applications and literally turn it on its head so the top of the receptacle is SMT soldered to the board while the body is standing above the board. In these applications the mating lead passes through a hole in the board, from the bottom, and plugs into the surface mounted receptacle on the top side of the board.

|

| ||

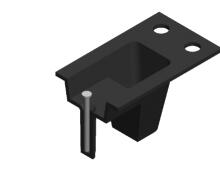

Nail Head Pins:Pick and place equipment has become more sophisticated in terms of the types of parts that can be picked up and the accuracy with which they can be placed. Due to these developments, some of the more popular pins we have been packaging are nail head pins in various diameters and lengths. Nail head pins are often used to connect multiple boards together in a through hole fashion. For these applications, the head of the pin is positioned at the top of the tape pocket where it is available to be picked up by the vacuum nozzle and delivered to the board. Some customers use nail head style pins as SMT interconnects where the head of the pin is soldered to the board surface. This means the head of the pin is at the bottom of the pocket and poses a greater challenge for pocket design, pin loading and keeping the pin stable enough so the nozzle can pick the part up consistently. Through our creative tooling design and packaging techniques we have been able to meet these challenges successfully.

|

| ||

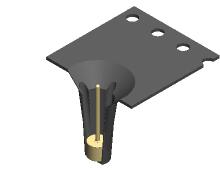

Double Tail Pins:Double tail pins are used for through-hole mounting, typically, in board stacking situations. They can be tricky both for packaging on tape and reel and picking and placing into the PCB by the end user. These pins tend to be on the longer side (greater than .250”) and often have small diameters (less than .030”) requiring the tape pocket to be deep drawn and designed to protect the pin during handling.

|

| ||

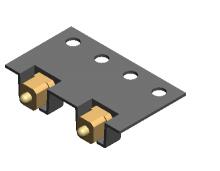

Horizontal Surface Mount Pins/Receptacles (HSMT):Horizontal surface mount (HSMT) pins and receptacles are typically used for mating boards or components in a horizontal orientation and for continuous connections (daisy chaining), commonly used in LED strip lighting. Since these parts are typically characterized with flat surfaces and have low profiles, they are ideal for tape and reel packaging. Our design experience and advanced precision machining techniques enable us to manufacture HSMT style products economically, with tight tolerances and in large volumes. We offer standard pins, receptacles and spring-loaded pins in this style.

|

| ||

Spring-Loaded (Pogo) Pins:Discrete spring-loaded pins have become ever more popular for uses such as board to board interconnects, docking stations for battery charging, and even power applications. Naturally, the demand for them packaged on tape and reel has grown. There are many different spring pin designs available and some are not suitable for tape and reel packaging. For these designs we offer individually insulated spring-loaded pins and spring-loaded pins with removable caps, both of which accommodate tape and reel processing efficiently.

|

| ||

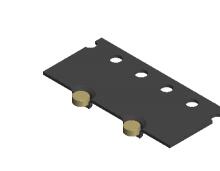

Target Discs:Target Discs are featureless flat “pins” that provide a durable surface and precise height profile as the mating components for spring-loaded pins. They are used in place of surface mount PCB pads allowing the design engineer to choose spring pins and target discs to tailor the interconnect height accurately. The low profile of these targets makes them ideal for tape and reel packaging as the pocket design is simple and the high quantity per reel results in fewer reel changes during production. Note, some surface mount components do not lend themselves well to being packaged on tape & reel due to their shape – relatively tall compared to their diameter is a typical problematic characteristic. These types of parts may only be available packaged in bulk; this can be a challenge for PCB assembly. For low volume assembly of discrete components such as nailhead style pins or flat bottom receptacles, hand placement or a semi-automated system may be acceptable. For medium to high volume assembly, a more efficient process is necessary. UMG Technologies, Inc. offers a pin feeder solution to handle bulk SMT components that works with your existing placement equipment. Read on below to learn about the features and capabilities of their SMV-90 Bulk Fed SMT Pin Feeder. You can also contact our technical services staff for more information on automation options or to discuss your application and how we may be able to address your needs. |

|