Introduction to Machined Pin PCB Connectors & Interconnects

PCB Connectors

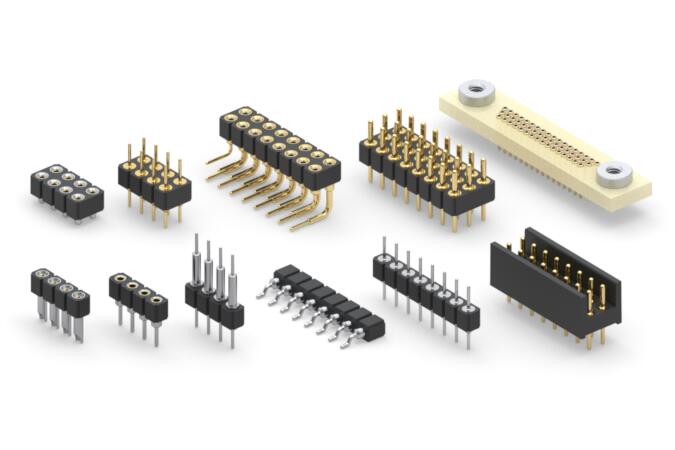

PCB connectors and interconnects are often referred to as sockets, headers, or rectangular connectors and are usually offered in many different styles and configurations. Machined Pin PCB connectors offer a highly reliable, precision-made interconnect solution ideal for a number of demanding application requirements in the world of board to board, cable to board, or component to board interconnects. Each Mill-Max connector is precision machined to ensure a high quality, low resistance, compliant connector giving it the edge over other technologies. Mill-Max’s innovative design leads the industry, enabling engineers to specify the right connector for their application.

Parts of the Machined Pin Interconnect

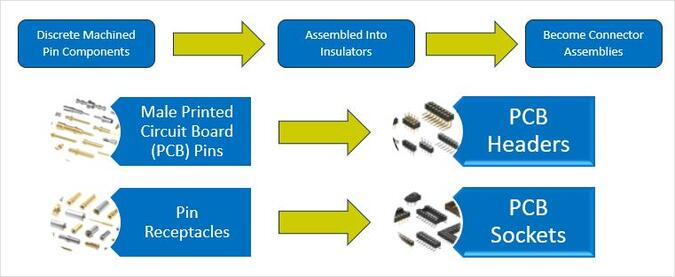

Mill-Max PCB connectors are made up of a discrete component machined from a metal alloy such as brass, phosphor bronze, or tellurium copper. For female interconnects a contact made from beryllium copper or beryllium nickel for high temperature requirements, is inserted to make a Receptacle, so that it can accept a lead .008" - .043" (0,20 -1,09) in diameter. The pin/receptacle contacts are then electroplated with tin/lead, lead free tin, or gold finish to ensure excellent electrical conductivity, durability and corrosion protection throughout the life of the product.

The machined pin or receptacle is assembled into high temperature thermoplastic or FR-4 housings in a standard or application specific footprint to create the final connector array.

Find your machined pin PCB connector

How Machined Components Become Connectors

Pin PCB Connector and Interconnect Options

Mill-Max offers a variety of options to accommodate everything from space-saving, fine-pitch requirements, to larger, more robust applications in which products are subjected to harsh environments including significant shock and vibration.

Standard connectors are available from .039” (1mm) to .200” (5.08mm) pitch as well as the capability to selectively load pins into specific grid patterns. Additional mounting hardware such as threaded inserts can also be incorporated into connector arrays to mechanically secure connectors to PCB boards or other substrates.

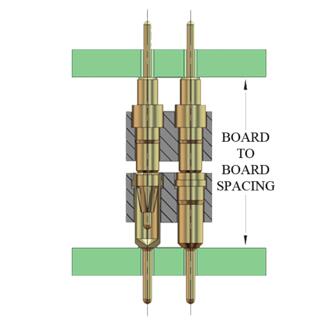

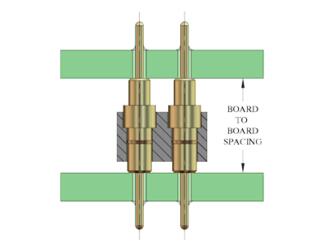

By mating different combinations of headers and sockets, a wide range of board-to-board spacing can be achieved. All standard sockets accept .008" - .043" (0,20 -1,09) diameter leads and are made using our unique Contact Clip, which provides a high reliability gas-tight seal.

Applications for Mill-Max PCB Connectors

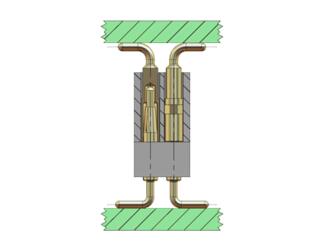

Pluggable Board-to-Board InterconnectsIn most board-to-board applications, designs require that the boards are pluggable. This allows for easy replacement in the event of board failure, more streamlined manufacturing for applications with multiple add-on board options and ease of upgradeability or accommodation of future design changes. In these type of applications, the same male headers in single and dual-row configurations are mated with female sockets. Mating different combinations of headers and sockets will create different between-board spaces. The header tail diameters need to be within the mating socket’s diameter acceptance range. | |

Permanent Board-to-Board ConnectionsIn some board-to-board applications, a designer may simply want to make a permanent connection between two boards. This can be readily achieved by soldering a Mill-Max through-hole header to both the main (mother) board and mezzanine (daughter) board. | |

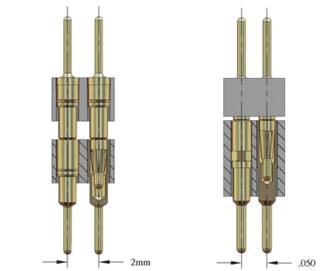

Fine Pitch Board-to-Board InterconnectsMill-Max has addressed the need to fit more components in less packaging space due to the ever-increasing demand for smaller and smaller electronic products with our fine-pitch connectors. Mill-Max offer standard interconnects in 1mm, 2mm, .070", .050" pin-to-pin spacing, and has the capability to produce application-specific products in 0,8mm pin-to-pin spacing, as well. | |

Low Profile and SMT Board-to Board InterconnectsAs a means of accommodating pc boards that are comprised entirely of surface mount components, Mill-Max offers surface mount headers and sockets in a variety of packages, from fine-pitch to .100" centers. These connectors eliminate the need for added processes, such as having to drill holes and wave solder pc boards that are otherwise comprised exclusively of surface mount components. These connectors can undergo reflow soldering with the other surface mount components, adding no extra steps to the solder process. | |

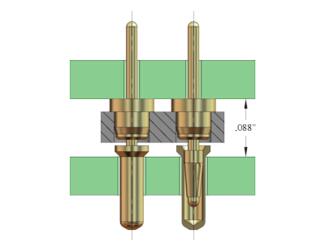

Low Profile Receptacle Carrier SocketsFor applications requiring boards to be mated very closely together to save vertical space, a carrier socket can be a perfect part of the solution. Mill-Max can provide virtually any receptacle on a carrier, in almost any configuration. The carrier socket is placed in position, allowing the receptacles to fall into the holes in a pc board. Only the shoulder of the receptacle rests on the surface of the pc board. After wave soldering, the carrier is removed and only the height of the shoulder is left above the board. Effectively, the entire "insulator" has been eliminated. Next, a male header is mated to provide for a very tightly-spaced, pluggable board-to-board interconnect. | |

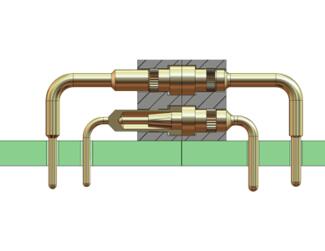

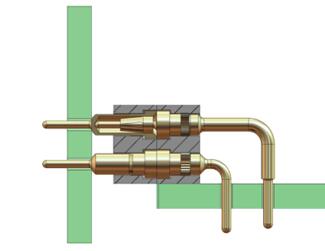

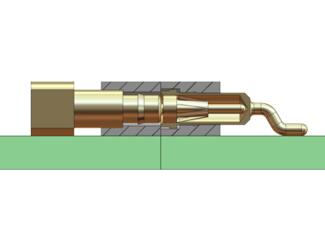

Horizontal Board-to-Board Connections using Right Angle and “Z-Bend” InterconnectsFor applications requiring boards to be plugged in on a horizontal plane, Mill-Max also offers right-angle sockets and headers. Mill-Max right-angle sockets and headers can also be used in tandem with vertical mount sockets and headers to create a perpendicular interconnect between two boards. Search Right Angle Interconnects

As a means of connecting two boards on a parallel plane using surface mount technology, Mill-Max offers HSMT connectors which are available with a or without a "Z-Bend" tail, or with removable caps to achieve a lower profile interconnect. | |

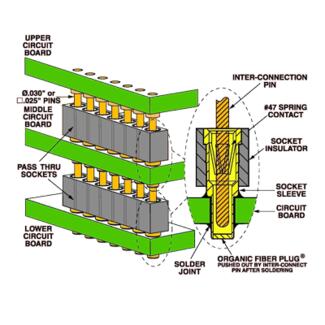

Stack Multiple Boards Using Organic Fibre Plug® SocketsWhen requirements dictate that three boards be joined together in a pluggable fashion, Mill-Max has addressed this need with our series 834 and 835 Organic Fibre Plug® Pass Through Interconnects. The Organic Fibre Plug® (OFP®) receptacle is an open-bottom, through-hole part with a "plug" made of organic material installed at the bottom. This plug protects the contact area from solder and flux contamination when the socket is installed into plated-through holes in a pc board. | |

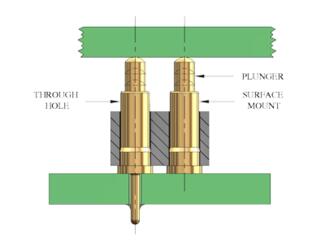

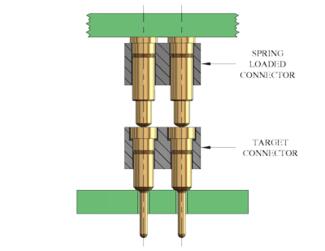

Spring-Loaded Board-to-Board ApplicationsFor applications where there is a wide variance on the spacing between two boards due to stack-up tolerances, Mill-Max's spring-loaded connectors are the perfect solution. Our spring-loaded pins interface with pads on a mating pc board to provide for a highly reliable connection that offers true compliancy for almost any design. Moreover, for applications where the between board space is unusually wide, Mill-Max offers Target Connectors to take up some of the gap. The Target Connector will help minimize the length of the lead on the spring pin connector so damage during handling doesn't occur due to the exposing of overly long plungers. Also, when a product's assembly doesn't offer the advantage of visibility for alignment of a traditional socket and header (known as a "blind mate") damage can occur to either the lead of the header or the retention feature of the socket. This problem is readily eradicated with a Mill-Max spring pin connector as the mating pad or Target Connector won't damage the plunger upon assembly. Available in both SMT and through-hole, loose pin, SIP, dual-row or custom configurations in non-standard pin spacing, Mill-Max's spring pin series help you connect with confidence. |

|

Need technical help or looking for a custom design? Contact us or review our custom capabilities.