Spring Loaded Pin Applications

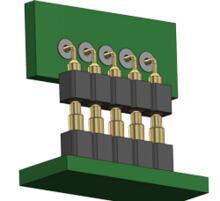

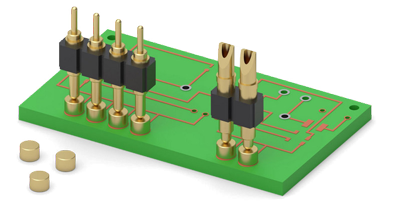

Board to Board

A typical application for the Mill-Max spring loaded product is a board to board connection requirement between two (or more) boards. Boards can be stacked on each other with the benefit of the spring movement to accommodate for tolerance stack-ups, misaligned boards and also errors in parallelism and co-planarity. This can be accomplished in many different ways using the Mill-Max spring-loaded pin. Whether the boards are parallel or perpendicular, vertical or horizontal, Mill-Max has a solution to offer. If real estate is limited we can offer spring-loaded connectors with a pin to pin pitch of .050” or 2mm. We also offer spring pins with an extremely low profile off the board to accommodate limited space in the Z or vertical axis.

Blind Mate

In some applications, aligning a traditional pin/receptacle combination can be difficult due to restricted visibility in the design. This is often referred to as a blind mate. Pin to receptacle misalignment during engagement can lead to broken or bent pins, damaged contacts and poor or missing connections. A spring-pin is an ideal solution to this as there is no insertion required. The spring pin connection is made with the plunger tip coming into contact with a conductive surface - typically a pad on a PCB or the face of a target pin. These mating surfaces are usually larger than the spring pin plunger which eliminates concerns about alignment and potential damage to components.

Battery / Device Charging

Spring-loaded pins are a perfect solution for charging batteries in portable instruments and docking handheld devices for data and power transfer purposes. They can be easily integrated into any system with numerous options available in terms of height, travel and spring force. Contact is made with the spring pin plunger tip. The spring pin allows for blind mating and some misalignment when placing the battery or device in the cradle, making it a good choice for this application.

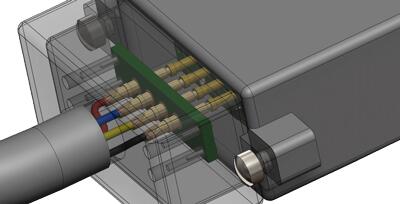

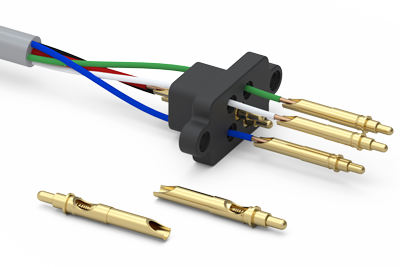

Cable Termination

Mill-Max spring-loaded pins with solder cup or wire crimp termination features can be used in wire or cable harness applications. Terminating the cable into a spring-loaded pin and over-molding or press-fitting the spring pin into a plastic housing allows the user to create a cable terminated connector with the advantages of a spring loaded contact as the connection point. Once again, this is excellent for blind mating and quick connect applications typically associated with cable connectors. The superior performance of Mill-Max spring pins under shock and vibration conditions provides sustained reliability in the long run, making them a good fit for the constant handling and jostling of cables.

Test Points

Mill-Max spring-loaded pins can be used as test points on boards which need to be verified after final assembly. They are well suited for high volume automatic test environments providing easy access and reliability.

Need technical help or looking for a custom design? Contact us or review our custom capabilities.