Frequently Asked Questions about Spring-Loaded Pogo Pins & Connectors

- What are Spring Loaded Pins?

- How do Spring-Loaded Pins work?

- What are Spring-Loaded Pins used for?

- What is the maximum stroke Mill-Max spring-loaded pins can provide?

- What is the recommended compression/travel range for Mill-Max spring-loaded pins?

- Are Mill-Max spring-loaded pins sealed or waterproof?

- Can Mill-Max spring-loaded pins be subjected to washdown procedures?

- How many cycles are Mill-Max spring-loaded pins tested to?

- What is the highest current rated spring-loaded pin Mill-Max can offer?

- Can Mill-Max spring-loaded pins mate with a dedicated pad on the opposing surface?

- Are Mill-Max spring-loaded pins or connectors lubricated?

- Are Mill-Max spring-loaded pins and connectors available on tape and reel?

- Do spring-loaded pins on tape and reel require a Pick and Place Cap?

- Are 3D models of Mill-Max spring-loaded products available

- Are there alternative plunger styles for Mill-Max spring-loaded pins?

- Can Mill-Max spring-loaded pins be customized

-

What are Spring Loaded Pins?

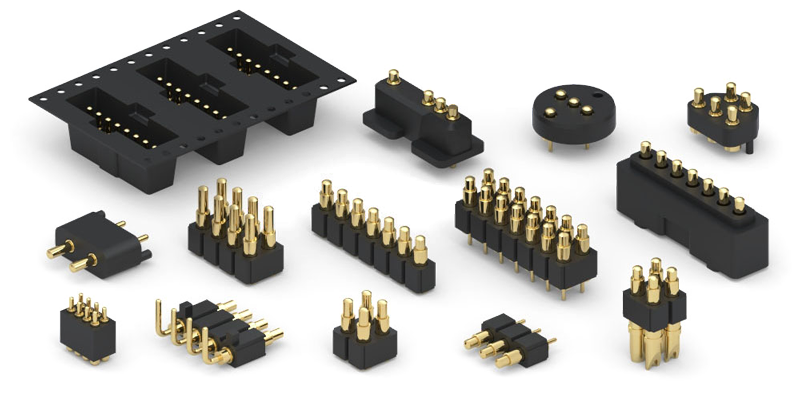

Mill-Max spring-loaded pins, also known as Spring-Loaded Contacts, or Pogo Pins, are an alternative interconnect solution for transmitting an electrical connection through its contact points. Mill-Max’s spring-loaded pins consist of a precision machined plunger, body, and cap, along with an internal spring which provides a range of mechanical movement when assembled. Mill-Max offers many options for spring-loaded pins that incorporate different compressions, diameters, overall heights, as well as spring force. Due to Mill-Max’s precision machining capabilities and extremely tight tolerances, a highly durable electrical connection can be achieved.

-

How do Spring-Loaded Pins work?

In a spring-loaded pin application, the plunger engages with a mating target contact and creates a surface pressure connection. As the spring is compressed and force is applied, and plunger moves inside the body. The primary path of travel is through the gold-plated outer components and the electrical interconnect relies on the force of the internal spring to maintain contact between the plunger and the mating component. The further the plunger is compressed; the more force will be applied at this single connection point which will result in greater electrical performance.

-

What are Spring-Loaded Pins used for?

Spring-loaded pins can be used in many electrical interconnect applications. Mill-Max offers spring-loaded pins in multiple configurations and stroke options which can be beneficial in applications with large stack up tolerances. Spring loaded pins are ideal for blind mating applications as the only connection required is for the plunger to engage with a mating target contact or contact pad. Whether the application is a simple board to board interconnect, or a more modular connection, Mill-Max has spring-loaded pins for your application.

-

What is the maximum stroke Mill-Max spring-loaded pins can provide?

Mill-Max offers standard spring-loaded pins with up to .118” [3mm} of maximum stroke.

-

What is the recommended compression/travel range for Mill-Max spring-loaded pins?

Mill-Max recommends their spring-loaded pins operate at mid-stroke compression for optimal electrical and mechanical performance.

-

Are Mill-Max spring-loaded pins sealed or waterproof?

Mill-Max spring-loaded pins are not IP rated but they have been used in waterproof/IP rated applications. A typical Mill-Max spring-loaded pin consists of 4 precision machined components. When a spring-loaded pin is compressed, the plunger will move inwards, residing inside the pin’s connector body. This movement will create an entry point for liquids or contaminants. For waterproof applications, Mill-Max spring-loaded pins can be installed into their own sealed housing that utilizes gaskets or O-Rings to create a sealed environment for the pins to function. For more information, contact us.

-

Can Mill-Max spring-loaded pins be subjected to washdown procedures?

While we do not provide any formal guidelines regarding washing down of our parts, we are aware of customers that have successfully performed this type of operation by using mild cleaning solutions, such as soap and deionized water. If your application requires the use of more aggressive cleaning solutions or procedures, we suggest testing it to ensure that it does not damage the spring-loaded pin or the gold plating finish. You also want to avoid using any solutions that will leave a residue that may hinder the movement of the plunger and/or internal spring.

-

How many cycles are Mill-Max spring-loaded pins tested to?

Most Mill-Max spring-loaded pins are tested between 100,000 to 1,000,000 cycles at the recommended mid-stroke compression.

-

What is the highest current rated spring-loaded pin Mill-Max can offer?

Mill-Max offers discrete spring-loaded pins that are rated for a maximum of 13A and derated to 10.4A. The derated current is to ensure safety margins for the product and is a 20% reduction of the maximum current. For more information on interpreting derating curves check out our

-

Can Mill-Max spring-loaded pins mate with a dedicated pad on the opposing surface?

Mill-Max spring-loaded pins can mate with any conductive surface. For optimal electrical and mechanical performance, we recommend mating against our dedicated target contacts and target discs.

-

Are Mill-Max spring-loaded pins or connectors lubricated?

Mill-Max Spring-Loaded Connectors are not lubricated. Customers have used light viscosity, thin metal oils in the past and have had success. Typical applications do not require lubrication.

-

Are Mill-Max spring-loaded pins and connectors available on tape and reel?

Most discrete spring-loaded pins can be packaged on tape and reel. Some factors that determine whether a part is suitable for tape & reel packaging include overall length, largest diameter, retention features etc.

Some Mill-Max spring-loaded connectors are available on tape and reel with a pick and place clip.

-

Do spring-loaded pins on tape and reel require a Pick and Place Cap?

Most spring-loaded pins are suitable for automatic pick and place so long as a suitable pick and place nozzle is used, however Mill-Max offers options with a cap. Several Mill-Max series include a pick and place cap to aid with assembly.

-

Are 3D models of Mill-Max spring-loaded products available

Step models for most Mill-Max products are available for download directly from the products webpage. Simply click on the “I Want To” drop down, followed by “Download 3D model”.

-

Are there alternative plunger styles for Mill-Max spring-loaded pins?

Most of Mill-Max’s spring-loaded pins have a plunger with a radius on the tip, however we can also provide flat and pointed tip plungers as an alternative option for most spring-loaded pins.

-

Can Mill-Max spring-loaded pins be customized

It is possible to modify existing Mill-Max spring-loaded pin designs as well as create completely new designs upon additional review with manufacturing. Most Mill-Max spring-loaded pins consist of 3 precision machined components and a spring. Modifying a spring-loaded pin will carry a one-time NRE tooling charge. There would be a MOQ of 1000 pieces for a custom spring-loaded pin. For more information view our Custom Capabilities.