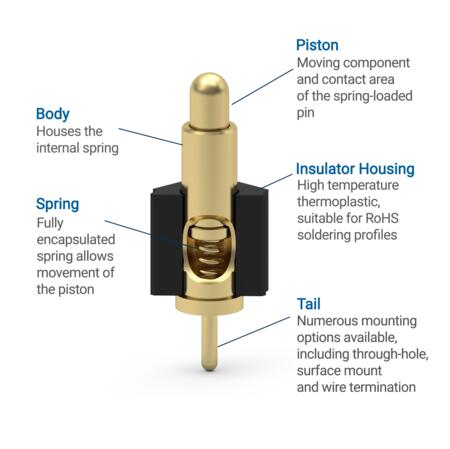

Introduction to Spring-Loaded Pogo Pins & Connectors

Spring-Loaded pins, sometimes called Spring-Loaded Contacts, Spring probes, or Pogo Pins, provide a highly-reliable, precision made interconnect solution ideal for a number of demanding application requirements in the fast moving world of electronic interconnects. Each Mill-Max spring-loaded pin is precision machined to ensure a high quality, low resistance, compliant connector giving it the edge over other technologies. Mill-Max’s innovative design leads the industry, enabling engineers to specify the right connector for their application.

|

THE BACKGROUND ON SPRING-LOADED PINS:

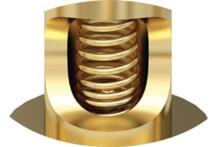

| Each Mill-Max spring-loaded pin is typically made of 3 machined components and assembled with an internal spring to provide the range of movement required. All of these components are electroplated with gold over nickel to ensure excellent electrical conductivity, durability and corrosion protection throughout the life of the product. Thanks to the many advantages spring-loaded pins offer, companies in the telecommunications, military, medical, transportation, aerospace and industrial automation industries have discovered the advantages of using spring-loaded pins in their design. |

SPRING-LOADED PIN & CONNECTOR OPTIONS | |

Whether your application requires through-hole mounting, surface mount, wire termination, press-fit or features for alignment, Mill-Max has multiple styles to choose from to ensure you find the right spring-loaded pin for your design. Features of most Mill-Max Spring-Loaded Contact Pins:

| 8 Reasons to Choose Mill-Max Spring Loaded Connectors

|

| Discrete Spring-Loaded Contact PinsField proven for performance and reliability in harsh environments, our discrete Spring-Loaded pins are tested to a minimum of 50g shock and 10g vibration with no spikes >1µs and > 1.5V with 0.5A applied. This ensures continuity across a wide variety of length and stroke configurations. Use our product finder to search for a specific style or consult with an applications engineer to discuss your requirements. |

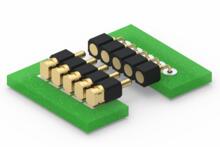

| Connector ArraysSpring-Loaded pins are often sold assembled into high temperature thermoplastic to form connector arrays. We offer several standard arrays from .050” (1,27mm) to ,158" (4,00mm) pitch, or we can selectively load pins into specific patterns. It is also possible to incorporate mounting hardware into the insulator such as threaded inserts to fixture the connector to a board or other substrate.

|

| Omniball® Spring-Loaded Contacts for Sliding and Rotational ApplicationsThese unique contacts offer an omni-directional mating surface allowing for sliding into place in blind mate or “twist & lock” applications. These contacts feature .030” (0,762mm) of vertical compression to ensure a quality electrical and mechanical connection, and offer a “wiping” connection, to ensure a cleaner contact surface. Omniball® spring-loaded contacts are ideal for horizontal and rotational connections as wear is minimized at the point of contact between the plunger and mating pad surfaces. |

| Maxnetic® Spring-Loaded ConnectorsWhen speed, precision, and durability matter, Maxnetic® spring-loaded connectors deliver. Designed with self-alignment and zero-force mating, these magnetic connectors simplify connections without tools or guesswork. From quick board-to-board setups to flexible cable assemblies, Maxnetic® offers the versatility to build faster and smarter. Choose from surface mount, through-hole, or wire terminations to meet your design needs. |

| Packaged on Tape and ReelMill-Max currently offers several discrete spring-loaded pins on tape & reel. Most spring-loaded pins can be removed from the tape packaging using modern automated assembly equipment, or in some cases may be packaged with a removable pick and place cap. Can't find what you need? Contact technical support to discuss packaging a particular part on tape & reel.

|

| Large Base Spring-Loaded PinsIncrease PCB stability with our discrete spring-loaded contacts featuring a larger base. These part families offer a range of application heights from .137" to .430" (3,48mm to 10,92mm.) and a base of .159" (4,00mm).

|

| Rugged, Higher-Current Spring-Loaded PinsMill-Max rugged spring pins are capable of carrying 9 amps continuous current at a low 30° C temperature rise. Employ high current spring-loaded pins in applications that need both power and ground pins. |

| Insulated Spring-Loaded PinsWhen your design requires a spring-loaded pin to pass through a conductive housing or isolate itself from nearby components a standard pin simply won't do. Our precision-engineered insulating sleeves provide a reliable dielectric barrier, preventing short circuits and protecting signal integrity. Insulated spring-loaded pins are the proven solution for creating secure, isolated connections in even the most demanding applications. Explore our Insulated Spring Pin Solutions.

|

| Spring Force OptionsMost Mill-Max Spring-Loaded pins are designed to maintain 60 grams of force at mid-stroke. For applications requiring a force higher or lower than the standard, a spring may already be available for the spring pin or connector you are interested in. The product detail pages of some spring-loaded pins indicate the spring force options available; you can also consult with an applications engineer to discuss your requirement and possibly have a custom spring designed

|

| Horizontal MountFor connections on a horizontal plane, we now offer a selection of horizontal mount spring-loaded interconnects. These pins and connectors are designed for parallel or right angle mating of boards and components. Available in .050" (1,27mm) or .100" (2,54mm) pitch in both through hole and surface mount. For the lowest profile option, be sure to check out our spring-loaded connectors with removable insulators.

|

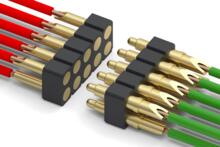

| Wire TerminationGo beyond board-level connections and create robust, reliable wire terminations with our specialized spring-loaded pins. For direct attachment, choose from our solder cups or crimp barrels, available in standard (up to 24 AWG) and large-scale (up to 16 AWG sizes. To accelerate your production, we now also offer a select series of spring-loaded connectors delivered with wires pre-crimped and ready to install. |

| Double Action Spring PinMechanically fastening stacked boards? Our double action spring-loaded pins are engineered to bridge the gap, providing a reliable electrical path between layers with a plunger on each end. If your design rules out soldering, our compression mount connector assemblies, utilize these same pins for a solderless solution.

|

| Power/Signal ConnectorsSpring-Loaded pins may also be arranged to make power and signal connectors by providing differing height and stroke spring pins in the same insulator for efficient combination connectors. Additionally, these First Mate/Last Break (FMLB) connectors can accommodate the requirements of hot swap connectors. Consult with an applications engineer for your specific requirements.

|

| Custom SolutionsIf you cannot find the exact product you are looking for from our standard line-up, we can work with you to design a custom pin or connector specifically for your needs. Contact our engineering department to discuss your design requirement. With low minimums and competitive pricing, we have the solution you need, whether it is for full production or prototyping volumes.

|