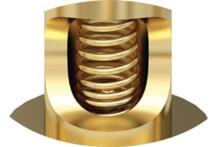

Spring Loaded (Pogo) Contact Connectors for Battery & Board Interconnects

When the power is on, you don't want shock or vibration to create spurious signals. Mill-Max Spring-Loaded (Pogo Pin) Connectors provide a reliable electrical connection in the most rigorous environments. These interconnects are typically used as the base unit (battery/charger) interface for portable equipment such as mobile phones/radios, bar code readers, medical and test instruments. They can also be used as a rugged surface-to-surface connector between circuit boards. See more detailed information and application notes on our Spring-Loaded Pin application page.

All pogo pin connectors have the following characteristics:

|

Mating Target Connectors provide a convenient mating surface for connecting with spring-loaded connectors, creating a reliable conductive path between modules. They offer an efficient solution for applications that require extending connectivity from one surface to another. For non-standard configurations, modifying a target connector is often more cost-effective and simpler than adapting a spring pin assembly, making it an ideal choice for flexible design needs.