Maximizing PCB Space with Zero-Profile Press-Fit Receptacles

As electronics become increasingly compact, the need for smaller connection solutions grows. This includes even the smallest areas of a device’s layout. Zero-profile press-fit receptacles support miniaturization in electronics enclosures, leading to more compact PCB configurations. Their robust construction supports demanding applications across industries such as consumer electronics, automotive, aerospace and medical devices.

What are Zero-Profile Press-Fit Receptacles?

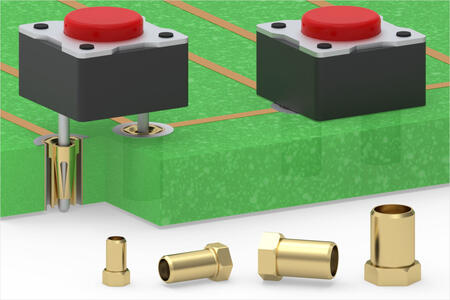

Designed to mount flush with the board, zero-profile press-fit receptacles are specialized PCB sockets that eliminate above-board protrusion and support ultra-thin form factors. Their hexagonal flange secures them in place, allowing for a stable connection. These receptacles are made from precision-machined brass with gold-plated beryllium copper contacts, providing strong conductivity and corrosion resistance.

Key Features

Zero-profile press-fit receptacles offer distinct design attributes that improve PCB configurations and simplify manufacturing.

Solderless Design

The press-fit connection forms a gas-tight bond within the plated through-hole (PTH), creating a secure electrical and mechanical connection without solder. This eliminates thermal stress and the risk of defects like bridging or cold joints.

Flush Mounting

With a hexagonal flange that is pressed in flush with the PCB surface, these receptacles remove above-board protrusion, allowing for lower-profile assemblies. This option is ideal for applications involving compact multi-board configurations or board stacking, where reducing height is imperative to meet space constraints.

Versatility in Lead Accommodation

With a choice of receptacles to accept lead sizes from 0.008" (0.2 mm) to 0.065" (1.65 mm), zero profile press-fit receptacles are compatible with a range of component types. Additionally, their open-bottom design allows leads to pass through without precise trimming.

Advantages in Assembly and Reliability

By leveraging these features, zero-profile press-fit receptacles enhance manufacturing processes and deliver dependable performance in challenging environments:

Streamlined Design

Eliminating above-board protrusion allows for more efficient PCB layouts in space-constrained applications.

Thermal and Mechanical Integrity

Press-fit connections withstand vibration, thermal cycling, and environmental stress more effectively than soldered joints. They provide the reliability to meet the needs of high-performance industries such as consumer electronics, automotive, aerospace and medical devices.

Simplified Assembly

Solderless installation reduces production steps and minimizes the risk of defects associated with soldering. This results in faster, more consistent assembly, reducing rework and overall manufacturing costs.

Mill-Max: Meeting Miniaturization Demands for Next-Gen Devices

By eliminating above-board protrusion, simplifying assembly and maintaining strong electrical connections, zero-profile press-fit receptacles offer a practical solution for compact, high-performance PCB configurations. Their precision-machined brass construction and press-fit design make them a durable and reliable choice for electronic packaging with stringent height requirements.

Mill-Max continues to develop advanced interconnect components that support the increasing demand for miniaturization without compromising performance. Contact our team to learn how zero profile press-fit receptacles can enhance your next project.