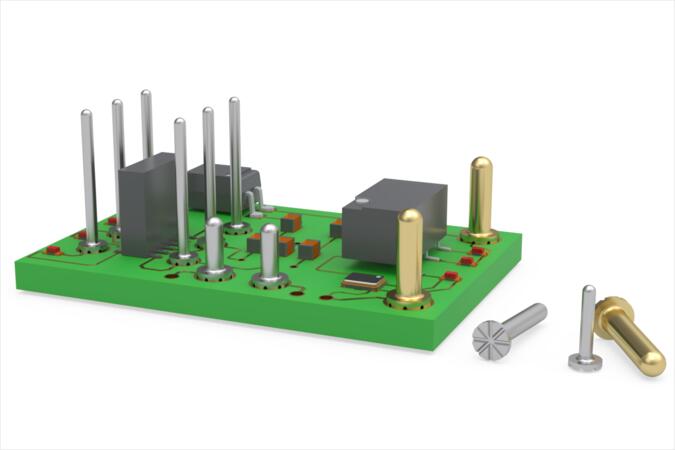

Sure-Hold Surface Mount PCB Pins

SMT terminals with integrated grooved base to provide a secure and consistent PCB connection

Mill-Max is expanding its range of SMT pins with the introduction of three new series featuring the Sure-Hold grooved base design. Each pin has four channels machined into the SMT base providing excellent solder flow and ensuring a secure soldered connection.

These new surface mount pins are nail-head in style, having two diameters, the base, and post. What makes them unique are the grooves, or channels, machined into the base of the pins. These channels fill with solder paste when the pin is placed on the PCB pad, acting as a tread to maintain location. During the reflow soldering process, the grooves promote efficient capillary action yielding optimal solder flow, which in turn, secures the pin to the pad in position and discourages the pin float often found with flat bottom pins. This results in more consistent pin positioning and perpendicularity which is critical for discrete pins.

There are three post diameters to choose from: .040” (1.02 mm), .060” (1.52 mm) and .080” (2.03 mm) – part numbers 1440-X, 1460-X, and 1480-X respectively. Each has a base diameter .060” (1.52 mm) larger than the post diameter, providing stable support during placement and soldering operations. 16 Pins are available in total with the 1440-X offered in lengths from .125” - .675” (3.18 – 17.15 mm); the 1460-X from .200” - .800” (5.08 – 20.32 mm), and the 1480-X from .250” - .680” (6.35 – 17.27 mm). Standard plating options are pure tin or gold, each with nickel under-plating.

The terminals are suitable for many uses in which surface mount connections are the only option, such as I/O and power connections where their relatively large size and durability are advantageous. They are also ideal for board-to-board interconnects, whether the requirement is low profile or a tall stack to clear other components, and there are a variety of Mill-Max receptacles they can readily connect to.

These pins are provided in bulk packaging. For high-volume applications, there are pin feeder options that may suit your needs and work in conjunction with existing pick & place equipment. Contact our technical services staff for more information on automation options or to discuss your application and how we may be able to address your needs.

Need technical help or looking for a custom design? Use the form below to contact Mill-Max Technical Services.